Flux-Cored Wire – The Basics of Welding and Factors to Consider

The flux-cored wire is an excellent option for welders who frequently need to weld outdoor materials or on unclean material; flux-cored welding can be a great option. Flux-cored welding is a technique that involves feeding a continuous hollow wire electrode into the weld joint through the welding gun. Self-shielded flux-cored welding varies from MIG welding in that it does not require an external shielding gas to protect the weld pool from contamination, such as carbon dioxide or argon. Instead, a flux compound in the wire acts with the welding arc to create a gas that shields the weld pool. Shielding gas is required for another procedure, gas-shielded flux-cored welding. flux cored welding wire manufacturers provide materials commonly utilized in heavy-duty industrial fabrication and production, and it’s not usually suggested for beginning or hobbyist use. Self-shielded flux-cored welding avoids the weld difficulties when a strong wind blows the shielding gas away while MIG is welding outside since the flux provides the shielding gas. The flux stored in the electrode also permits the process to be more tolerant of rusted, filthy, or otherwise contaminated base metal. Like stick welding, flux-cored welding produces a slag that rests on top of the final weld and must be chipped off, and it also produces welds that aren’t as visually appealing as MIG welds. For these reasons, switching to the MIG process for indoor welds makes sense if you have a power supply capable of doing MIG and flux-cored welding. Why procure consumables from flux cored wire manufacturers, and How Does It Work? The process involves a constant-voltage welding power source, continuous wire-fed electrode, and the same equipment utilized in metal active gas welding in welding procedures (MAG welding). Flux-cored arc welding, which may be done with or without shielding gas, is far more efficient and cost-effective than MAG welding. Flux cored wire manufacturers provide top-quality consumables with which the heat generated by an electric arc is used to combine the base metal in the weld joint region. It employs a hollow or tubular electrode filled with a flux-cored wire that forms a gas to protect the weld pool. The procedure is widely used in outdoor welding and on contaminated materials due to the penetrative capabilities of flux-cored wires and high deposition rates. External shielding gas is not required for flux-cored arc welding to protect the weld from the elements. When the material is used on thick materials, it produces “slag.” You can carve it out later to make it look cleaner and more polished. Factors to consider while using welding consumables from Flux cored wire manufacturers 1. Preparing the Flux-cored welding from flux cored welding wire suppliers is more forgiving of surface contamination than MIG welding. However, it’s always a great idea to clean the base metals’ surfaces as precisely as possible to avoid contaminating the final weld with a rusty or scaly surface. Cleaning the basic metals is easy using a metal brush or grinder. Make sure the area of the base metal in which the ground clamp will be fastened is clean as well. Poor ground clamp contact will cause resistance in the welding circuit, leading to poor weld quality. Cored welding wire manufacturers suggest sharpening the edges of the base materials for anything over 1/4 inch to ensure perfect fusing of the two components. This is particularly true in the case of butt joints. 2. Amperage and voltage Metal thickness, joint arrangement, welding position, and wire diameter all influence how much voltage and amperage a weld requires. On your power supply, there are reference tables to help you establish the proper voltage and wire feed speed based on the wire diameter and material thickness. A wonderful tool to use is our flux-cored welding calculator. These tools should be used as approximate guidelines, with a few test welds to fine-tune your final specifications. 3. Equipment Preparation A. Examine your cords: Check your welding equipment before striking an arc to ensure sure all of the cable connections are secure and free of fraying or other damage. For better results make use of the consumables from top flux cored welding wire dealers. B. Choose the polarity of the electrodes: DC electrode negative, or straight polarity, is required for flux-cored welding. The polarity connectors are normally situated near the drive rolls on the inside of the machine. C. Make sure you are using the right drive rolls: Because the flux-cored wire is softer than solid wire, knurled drive rolls provide the wire with a good “bite” without crushing and deforming it, as normal drive rolls might. D. Check the tightness of the wires: Poor wire feeding performance can be caused by too much or too little strain on the drive rolls or the wire spool hub. Adjust according to the instructions in your owner’s handbook. E. Examine the consumables: Remove any excess splatter from contact tips, replace damaged contact tips and liners, and throw away the wire if it appears to be rusted. Make the welding process of your plant more seamless and effective with flux cored welding wire manufacturers in MumbaiGet a free Quote!

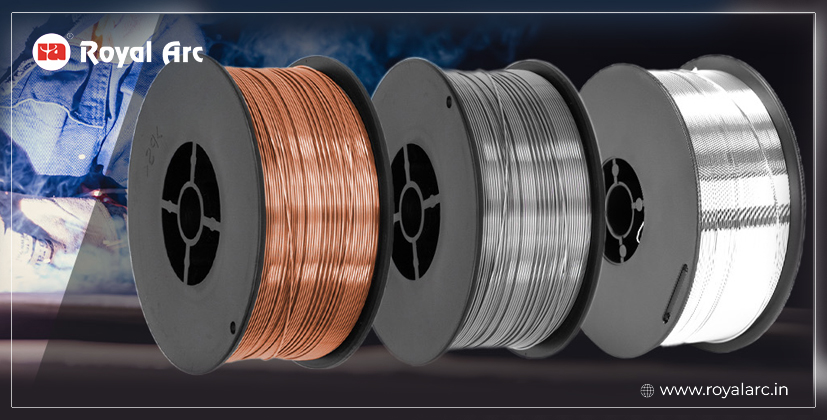

MIG/TIG Wires and the Welding Process: Everything You Need to Know

Welding is a fabrication procedure that includes applying heat and pressure to two separate material pieces to create a durable joint. MIG wire supplier provides various types of welding consumables suitable for the specific welding process. Industry professionals use various welding techniques to form the desired assemblies, depending on the part and manufacturing criteria. MIG and TIG welding are two of the most prevalent welding processes. If you’ve ever wondered how MIG and TIG welding differs, this blog post will provide you required insights. What is MIG Welding Wire, and How Does It Work? MIG welding is known as Metal inert gas welding. The name inert gas refers to the characteristic that the arc does not react to oxygen in the atmosphere. The electric arc is surrounded by a shielding gas that prevents it from acting outside its defined area. This gas contributes to MIG welding’s increased safety. Large and thick materials typically make use of MIG welding. The process uses a disposable wire that serves as both an electrode and a filler material. It is substantially faster than TIG welding, resulting in shorter lead times and cheaper production costs. MIG welding wire manufacturers offer great consumables that are simpler to execute and create welds that don’t need much cleaning or polishing. On the other hand, its welds are not as highly precise, clean, or durable as TIG welding. The welder uses a consumable electrode in the form of a metal filler. This metal will melt to join the metal parts that the welder wants to join. The sort of electrode filler you choose is determined by the materials you’ll be joining and their characteristics. MIG Welding Wire has the following characteristics: 1. Compared to other welding types, MIG welding is a simple operation. 2. The process is rapid because of its simplicity, making it excellent for last-minute applications, especially when joining more significant metals than TIG welding can handle. 3. MIG welding aids in a quick process. 4. MIG welding filler adheres to metal pieces better, and thicker metal takes longer to heat for TIG welding to operate. Products from MIG welding wire manufacturers for various application CO2 MIG wire manufacturers in India offer welding consumables for various applications, including: ● Metal component repairs● Trailer hitches● Automotive repairs and manufacturing● Farm equipment● Pipe welding● Construction welding● Railroad track repair● Underwater welding projects● Shipbuilding What is TIG Welding, and How Does It Work? TIG stands for tungsten inert gas welding. This electrode is a consumable metal that provides the filler in MIG welding. On the other hand, tungsten does not melt as quickly as other metals, and it generally conducts the arc of electricity to the materials you need to join. TIG wires from co2 wire manufacturers have a wide range of applications, allowing industry professionals to blend various small and thin materials. It heats the metal with a non-consumable tungsten electrode and can be employed with or without filler. It is substantially slower than MIG welding, resulting in longer lead times and higher manufacturing costs. Welders also require specialised training to ensure they attain the required precision and accuracy. It does, however, provide more control during the welding process and results in strong, precise, and visually beautiful welds. It is substantially slower than MIG welding, resulting in longer lead times and higher manufacturing costs. Welders also require specialised training to ensure they attain the required precision and accuracy. It does, however, provide more control during the welding process and results in strong, precise, and visually beautiful welds. TIG does not require a filler, but MIG does. Because of its capacity to join two metals without using a filler, the parts have a cleaner junction that is free of faults caused by filler material that has been overused. TIG welding takes a long time because of its requirement for precision, and TIG welding takes at least twice as long as MIG welding on a similar project. However, investing in TIG ensures that the TIG welding product has a smooth, exact weld between two metal sheets. TIG Welding Process – Procurement from co2 wire manufacturers TIG welding requires two hands if employing a filler material, unlike MIG welding, which has just only one hand to operate the welding torch, albeit two hands for steadiness is preferred. During TIG welding, you hold the filler with one hand while inside the welding torch in MIG welding. In the TIG welding method, tungsten replaces the consumable filler that would be used in MIG welding. This tungsten maintains its shape throughout the process, allowing for multiple uses. Application of TIG Welding wires TIG is ideally suited for situations where appearance and strength play vital roles, requiring exceptional precision and generating cleaner welds. TIG produces completed goods with no visible weld filler above the surface when operating without filler. TIG does not produce splatter since it does not require filler to form a bond. Building codes mandate some applications of TIG welding. At least the first weld between the parts must use TIG welding for several projects. Some examples include Pipes, visible consumer products, and nuclear work. TIG welds are ideal for attaching vehicle body parts, aerospace components, ship parts, bicycle parts, and pipes since they have no visible filler when finished. The corrosion resistance and strength of TIG welds are important in these applications. TIG welding usage in spent nuclear fuel is one application that demonstrates its strength and dependability. After nuclear rods have served their purpose, welders utilize TIG welding to encapsulate these still radioactive materials, preventing material leakage. To learn more about the capabilities of the MIG welding wire manufacturers in India? Request a Quote

Different Types of Electrodes & its characteristics

Welding electrodes are utilised in a variety of industries, including autos, construction, and so on. Electrodes are utilized to create an electric arc when welding two pieces of metal together. The metals heat up and melt together, forming a stronger bond. The outer flux layer on the welding rod protects the metal, stabilises the arc, and enhances the weld. The electrode falls under 2 main categories, either consumable or non-consumable, depending on the welding procedure. For a job, it must be carefully chosen. Different kinds of welding rods have other characteristics. Welding Electrode Manufacturers provide electrodes in various shapes and sizes, which consumers can choose from. Each has characteristics that make it perfect for a specific use. Electricity is pulled through an electrode in welding applications, resulting in an arc of electricity at the electrode’s tip. When the arc at the edge of an electrode is dragged onto a workpiece, welds are formed. Many electrodes melt and are deposited onto a workpiece, forming a metallic filler, while others do not melt and provide a place for an electric arc to occur. How Many Types Does a Welding Rod Manufacturer Offer? To make strong welds, welders must utilize various materials, but do you understand the different kinds of welding electrodes? The thickness of the metals, the type of base metals, and the current you use to weld all impact your electrode selection. How many various kinds of welding electrodes are there? Consumable and non-consumable electrodes are the two types of electrodes. Consumable electrodes are used by arc welders and MIG welders, whereas TIG welders use non-consumable electrodes. Why Welding Electrode Manufacturers Cover the Electrodes? When molten metal is exposed to air, it absorbs nitrogen and oxygen, which causes it to deteriorate and become brittle. To protect molten/solidifying weld metal from the atmosphere, welding rod suppliers use a slag blanket would be required, however, electrode coating offers this protection. The coating composition of welding electrodes determine their utility and, as a result, the composition and specification of the deposited weld metal. Welding rod wholesale supplier develops welding electrode coatings using well-established metallurgy, chemistry, and physics principles. Arc stabilisation provided by the coating improves welding in the following methods.1. A minimum amount of spatter in the welding zone2. A smooth weld metal surface with even edges3. A welding arc that is both stable and smooth4. A robust and durable finish5. Simple slag removal6. A higher rate of deposition7. Welding penetration control What Are the Various Welding Electrode Types? You are more likely to utilize a consumable electrode unless you do TIG welding. The only exception is if you utilize carbon electrodes in an arc welder. Carbon electrodes are formed of carbon graphite and are non-consumable. Welding electrodes manufacturers in India provide the below electrode types. Non-Consumable Electrodes Carbon and tungsten electrodes are examples of non-consumable electrodes. In residential and industrial applications, tungsten rods for TIG welding are more frequent than carbon rods. Carbon Electrodes Carbon arc welding is a less common and older type of welding. CAW is a procedure you’re unlikely to encounter in a welding shop even though it’s still used today. Consumable Electrodes Consumable electrodes are the most popular electrode type, and they are used by both MIG and Shielded Metal ARC welders. Consumable electrodes, unlike non-consumable electrodes, melt throughout the welding process. Welding electrodes manufacturers in Mumbai supply MIG electrodes that are made of a thin wire that is automatically supplied into the welding gun by the MIG machine. Human-operated MIG welders are regarded as semi-automatic welders, while robot-operated MIG welders are considered fully automatic. MIG wire is not coated with flux because MIG machines use a shielding gas to protect the weld. Bare electrodes are used to weld manganese steel since they don’t have a flux covering to protect the weld pool. Arc welders prefer coated electrodes offered by welding rod manufacturers in India are split into three categories. • Electrodes with a light coating• Electrodes with a medium coating• Electrodes with a thick coating or shielded arc electrodes Light Coated Electrodes Light coated electrodes contain a thin flux coating, as the name implies. The flux shields the weld pool against contaminants such as phosphorus, sulphur, and oxides, even though it does not provide a dependable shielding gas. Medium Coated Electrodes Medium coated electrodes, such as low-hydrogen rods, are commonly used by both novice and experienced welders. Offshore drilling, commercial building construction, bridge construction, and pipeline welding are just a few of the applications for medium-coated rods. Medium-coated electrodes have a coating factor of 1.45 and are characterised by readily removed slag, excellent arc control, and the capability to weld in all positions. Heavy Coated Electrodes Heavy coated electrodes have a coating factor of 1.6 to 2.2 and contain the most flux. When the coating is fired in the weld pool, it produces a shielding gas that protects the weld. The rods are made up of 3 different materials: cellulose, mineral, and cellulose plus mineral combination Takeaway Even if you know the various welding electrodes, selecting one for a specific product can be tricky. Before you start welding, you need to figure out what kind of welding rod you’ll need. Each of these electrodes is given a name based on a set of characteristics. If you are looking for more guidance, give us a call! Royal Arc is one of the leading welding rod manufacturers in Mumbai

Understand the Flux-cored wire variants, characteristics & applications

Flux-cored wire manufacturers in Mumbai produce cored wires that are produced by infusing a steel strip in pipe form with numerous chemical substances. Flux cored wire can be utilised with any GMAW machine, with or without a gas shield. The procedure is called “Flux Cored Arc Welding.” Cored wires are available in two configurations: folded and seamless. Folded flux-cored wires are formed by bending strips in a u-shape similar to a seamed pipe, filling them with a powder core (an alloy composition), and rolling them like a thin pipe. Seamless flux-cored wires are formed by filling the core with a seamless steel pipe band. Flux-cored wires enable welding in all locations and allow for the use of a single product in all manufacturing and alloy types. The variety of base materials precluded this product from being a “one-product-for-all-alloy kinds” concept, which was one of the primary goals of this product’s creation. However, material science continued to advance, and high-tech materials began to take centre stage in the welding industry. There is no one-size-fits-all filler metal. Among other factors, the mechanical and chemical qualities of the base material, the needed welding location, the available equipment, and the welding operator’s skill set all play a role in determining the optimal option. When increasing productivity through increased deposition rates, flux-cored wires are frequently a suitable alternative. These wires are well-known for their outstanding performance and weld quality in various industries, including general fabrication and manufacturing, as well as offshore, construction, and ship building. Flux-cored wire suppliers offer consumables with distinct welding characteristics and fulfills the various needs. Understanding their characters, advantages and disadvantages can assist you in determining whether they are the best option. Products from Cored wire manufacturers with different Types and Characteristics Cored wire manufacturers offer products in self-shielded and gas-shielded variants, with some designed for use in all positions (for example, American Welding Society [AWS] E71T-1C) or for flat and horizontal applications (E70T-1C). Both are gas-shielded and produce a slag that assists in protecting the liquid weld metal during cooling, but one should remove the slag after welding and between passes. These wires are available in various base metals, including mild steel, low-alloy steel, stainless steel, and nickel alloys. They are available in tensile strengths of up to 70 KSI for mild steel welding and 80 to 120 KSI for high-strength, low-alloy steel welding. When an arc is initiated, self-shielded flux-cored wires (FCAW-S) generate their shielding gas, removing the requirement for an external gas cylinder and making them ideal for use in portable and distant applications. However, these wires emit slightly more smoke and spatter than gas-shielded flux-cored wires. Reliable flux-cored wire dealers offer products in many categories that exhibit excellent impact durability, especially at low temperatures. The flux that is self-shielded-cored wires is frequently used in place of shielded metal arc welding (SMAW) electrodes to boost productivity due to their continuous feed and lack of recurring downtime for changeover. Gas-shielded flux-cored wires (FCAW-G) require either pure CO2 or a mixture of argon and CO2 as an external shielding gas. They have a greater operator appeal, which means they are easier to handle and employ to create a visually pleasing weld. They are primarily utilized in a retail context. When used outside, FCAW-G wires may require a barrier, such as a tent or some other method of protecting the weld pool from blowing away the shielding gas. Get durable welding consumable – Flux-cored wire manufacturers in Mumbai Flux core welding, also known as tubular electrode welding, originated from MIG welding to increase the arc action, metal transfer, weld metal characteristics, and weld aesthetics. It is an arc welding technology that utilises an arc between a continuously supplied tubular electrode wire and the workpiece to generate heat for welding. The flux-cored welding wire, or electrode, is a hollow tube filled with deoxidizers, fluxing agents, metal powders, and ferroalloys. The only noticeable difference between flux-cored and solid cold-drawn wires is the closing seam, which is a fine line. There are two methods for flux-cored electrode welding: Carbon dioxide gas can be utilised in conjunction with the flux to increase shielding. The flux core can supply all shielding gas and slagging materials on its own. Benefits of procuring materials from cored wire manufacturers 1. It will boost manufacturing speed by 10% to 40% due to the high deposition speed (weld metal/min).2. It is capable of welding in any position.3. It ensures superior mechanical characteristics and hardness with a precise microstructure with minimum heat input compared to conventional processes.4. It is possible to weld open-arc (without the use of shielding gas).5. In the medium and high alloy product categories, the cost per kilogram is less than solid wire. Flux-cored wire manufacturers have complete control over the formulation of their products (core content). Thus, the weldability of cored wires is superior to that of some GMAW wires. This is a more rapid procedure than the electrode method. Metal-cored formulations are slag-free and ideal for robotic multi-pass applications. Proper technique and operation, when combined, can result in increased weld quality and production while also minimizing costly downtime.

Everything you need to know about gas shielded and self-shielded flux cored wires

Do you need to weld in difficult-to-reach places or on heat-sensitive metals? If so, then you should consider using flux cored wires as it is beneficial over other welding methods. Some key benefits include: – Reduced distortion of the welded metal – Little to no spatter – Easy joint preparation Gas shielded and self-shielded flux cored wires are two of the most popular types of welding wire available today. We will discuss the differences between gas-shielded and self-shielded flux-cored wires and their benefits. We will guide you in choosing the right type of welding wire for your needs. Overview Gas shielded wires Gas shielded flux-cored wires are made of a metal wire core covered with a flux compound. These wires are often used in construction and industrial applications. Gas-shielded flux cored wires are known for their excellent arc stability, and low spatter levels. Hence, they are ideal for welding in difficult-to-reach places, such as inside a car door or frame. They are also great for welding thin materials because they provide a very strong weld without causing the material to warp. Benefits of Gas shielded flux cored wires: – Provide a much higher deposition rate than solid wires. – Produce less welding fumes than stick electrodes, and the fumes produced are easier to control with ventilation. – Have a very low spatter level, which results in less cleanup time and less rework. – Available in various diameters and packaging types to suit different applications. – Used with either AC or DC power sources, making them versatile for use in different welding environments. Self-shielded flux cored wires Self-shielded flux-cored wires are not as stable as gas-shielded wires, but they have benefits. These wires are easier to use than gas-shielded wires because you do not need to monitor the gas pressure. It makes them ideal for beginners or anyone who does not want to deal with the hassle of setting up and monitoring a gas tank. Another benefit is that they are less expensive than gas-shielded wires. It makes them an excellent choice for budget-conscious welders. If you are looking for an easy-to-use wire that is less expensive, then a self-shielded flux-cored wire is a great option. If you need a more stable wire that provides a stronger weld, then the gas-shielded flux-cored wire is the way to go. Benefits of self-shielded flux core wires There are several benefits of using self-shielded wires. It helps in a wider range of applications than other wires. It provides better protection against electromagnetic interference (EMI). Also, it improves the performance of electrical equipment by reducing resistance and increasing conductivity. Overall, self-shielded wires offer many advantages and should be considered for any application where EMI protection is required. Gas-shielded flux-cored wires are more expensive than self-shielded, but they offer several advantages. Gas shielded wires produce less smoke and fumes, which are better for indoor welding applications. They also have a higher deposition rate, so you can weld faster with them. Finally, gas-shielded wires provide better penetration and bead appearance. Self-shielded flux cored wire is a good choice if you are welding outdoors or in a well-ventilated area. It’s less expensive than gas shielded wire and easier to use because you don’t need to connect it to a shielding gas tank. A self-shielded wire is available in various sizes and strengths to find the right one for your welding project. Takeaway Now that you know the difference between gas-shielded and self-shielded flux-cored wires, you can decide which is right for your next welding project. Choose the wire that will give you the best results for your application. If you are looking for a flux-cored wire manufacturer, get in touch with us!

Welding Electrodes and Tips to Get the Best Output: A Comprehensive Guide

Welding electrodes are an important part of the welding process. They provide heat and metal to create a weld. Understanding the different types of electrodes is important to understand the best results from your welding electrodes. This comprehensive guide will discuss the different types of welding electrodes and tips on how to use them effectively! Different Types of Welding Electrodes Three types of welding electrodes are bare, coated, and gas-shielded. Each type has advantages and disadvantages that you should consider when choosing the right electrode for your project. Bare Welding Electrodes Bare welding electrodes are the most common type of electrode. They come in various metals, such as copper, aluminium, stainless steel, and steel. Bare electrodes are easy to use and provide good welds. However, they can be more challenging to control than other electrodes. Additionally, bare electrodes produce more sparks and require more power to operate effectively. We recommend starting with a bare electrode if you are new to welding. Coated Welding Electrodes Coated welding electrodes are covered in a material that helps to protect the metal from oxidation. This can be helpful when welding metals susceptible to rust, such as iron or steel. Coated electrodes also provide better arc stability and produce fewer sparks than bare electrodes. However, they can be more expensive and difficult to find than bare electrodes. Additionally, coated electrodes require more power to operate effectively. If you are experienced with welding, we recommend using a coated electrode. Gas-Shielded Welding Electrodes If you are experienced with welding, we recommend using a gas-shielded electrode. Gas-shielded Welding electrodes are surrounded by a gas that protects the weld from contamination. This is helpful when welding metals sensitive to contamination, such as aluminium. Gas-shielded electrodes also provide better arc stability and produce fewer sparks than bare or coated electrodes. However, they can be more expensive and difficult to find than other types of electrodes. Additionally, gas-shielded electrodes require more power to operate effectively. Tips for Using Welding Electrodes If welding with an electrode is too small, you will have to work harder to get the job done right. That’s why it’s important to choose the right electrode for the job. Here are some tips to help you select the best welding electrodes and get the most out of your welds. Here are some tips for getting the best results from your welding electrodes: Choose the correct type of electrode for your project. As we mentioned above, each electrode type has its advantages and disadvantages. Make sure to select the type of electrode that is best suited for your project. Different metals require different types of electrodes. For example, if you are welding stainless steel, you will need a different electrode than working with aluminium. The type of metal you are welding will also affect your welder’s amperage and voltage settings. Consult your welder’s owner’s manual for the proper settings. Electrode Diameter If you are welding thin materials, you need a smaller diameter electrode. Consult your welder’s owner’s manual for the proper electrode size. Set the proper power level Welding electrodes require a certain amount of power to operate effectively. If you set the power too low, the electrode will not be able to create a weld. If you set the power too high, the electrode will overheat and damage the metal. Use proper technique Welding is a skill that takes practice to master. Make sure to use proper technique when using welding electrodes. If you are unsure how to weld properly, we recommend getting help from welding electrode manufacturers. Electrode tip style Choose an electrode tip style compatible with your welder. The most common tip styles are E-series (for AC welders) and T-series (for DC welders). Check the manual to determine the suitable electrode tip style. With theseThese tips will help you select the best welding electrodes for your next project. Welding electrodes are an important part of any welder’s toolkit. By following these tips, you can be sure to choose the right electrode for the job and get the most out of your welds. If you want more information on welding or welding supplies, check out our website or give us a call today.

All You Need to Know About Flux Cored Wires: Different Types and Applications

Regarding welding, flux cored wires are one of the most popular options. This blog post will discuss different types..

6 Factors to Consider When Choosing Flux-Cored Wires for Your Project

When it comes to choosing flux cored wires for your project, there are a few factors you need to take into account.

Flux cored wires: How to choose the perfect one for your project.

Flux cored wires are a popular choice for welding. However, the secret for efficient execution lies with the appropriate..

Different welding electrode types, their characteristics and applications

Understanding the most common types of welding electrodes, their properties and applications will help in choosing..